8

Vacuum supply

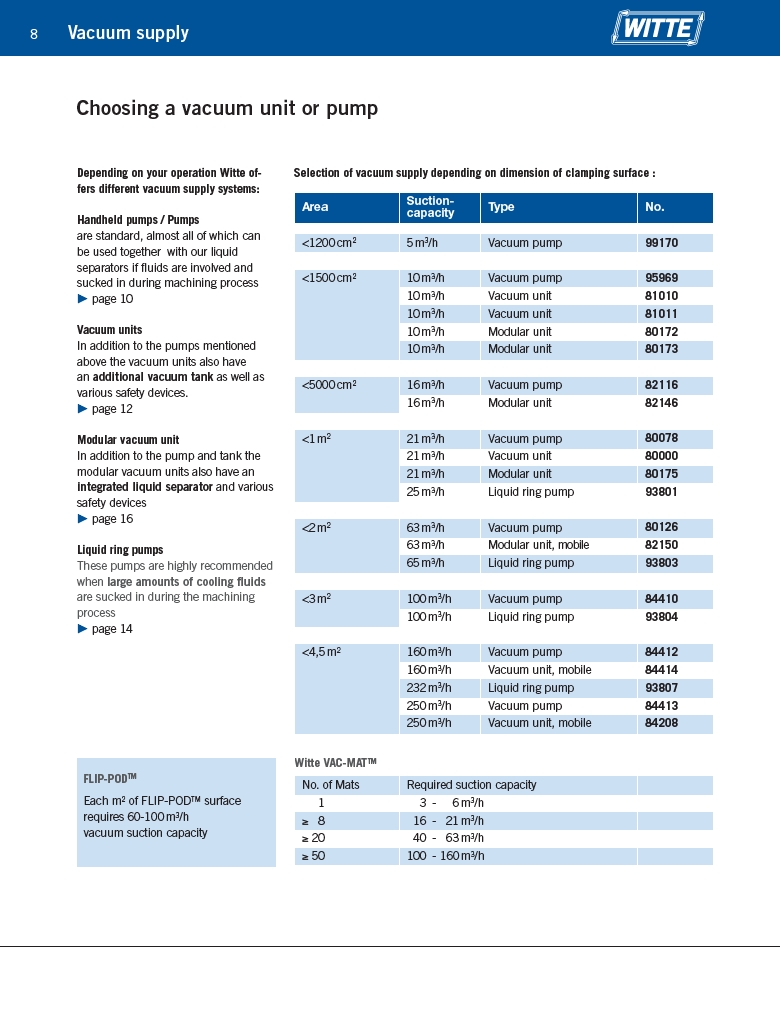

Choosing a vacuum unit or pump

Depending on your operation Witte offers

different vacuum supply systems:

Handheld pumps / Pumps

are standard, almost all of which can

be used together with our liquid

separators if fluids are involved and

sucked in during machining process

page 10

Vacuum units

In addition to the pumps mentioned

above the vacuum units also have

an additional vacuum tank as well as

various safety devices.

page 12

Modular vacuum unit

In addition to the pump and tank the

modular vacuum units also have an

integrated liquid separator and various

safety devices

page 16

Liquid ring pumps

These pumps are highly recommended

when large amounts of cooling fluids

are sucked in during the machining

process

page 14

Selection of vacuum supply depending on dimension of clamping surface :

FLIP-PODTM

Each m2 of FLIP-PODTM surface

requires 60-100m3/h

vacuum suction capacity

Area Suctioncapacity

Type No.

<1200cm2 5m3/h Vacuum pump 99170

<1500cm2 10m3/h Vacuum pump 95969

10m3/h Vacuum unit 81010

10m3/h Vacuum unit 81011

10m3/h Modular unit 80172

10m3/h Modular unit 80173

<5000cm2 16m3/h Vacuum pump 82116

16m3/h Modular unit 82146

<1m2 21m3/h Vacuum pump 80078

21m3/h Vacuum unit 80000

21m3/h Modular unit 80175

25m3/h Liquid ring pump 93801

<2m2 63m3/h Vacuum pump 80126

63m3/h Modular unit, mobile 82150

65m3/h Liquid ring pump 93803

<3m2 100m3/h Vacuum pump 84410

100m3/h Liquid ring pump 93804

<4,5m2 160m3/h Vacuum pump 84412

160m3/h Vacuum unit, mobile 84414

232m3/h Liquid ring pump 93807

250m3/h Vacuum pump 84413

250m3/h Vacuum unit, mobile 84208

Witte VAC-MATTM

No. of Mats Required suction capacity

1 3- 6m3/h

≥ 8 16 - 21m3/h

≥ 20 40 - 63m3/h

≥ 50 100 - 160m3/h