62 Vilmill

Vilmill&Vacuum

Partners for high-speed cutting of aluminium and plastics

If your job is to cut lots of small parts out of one large part the

combination of vacuum and Vilmill is what you need.

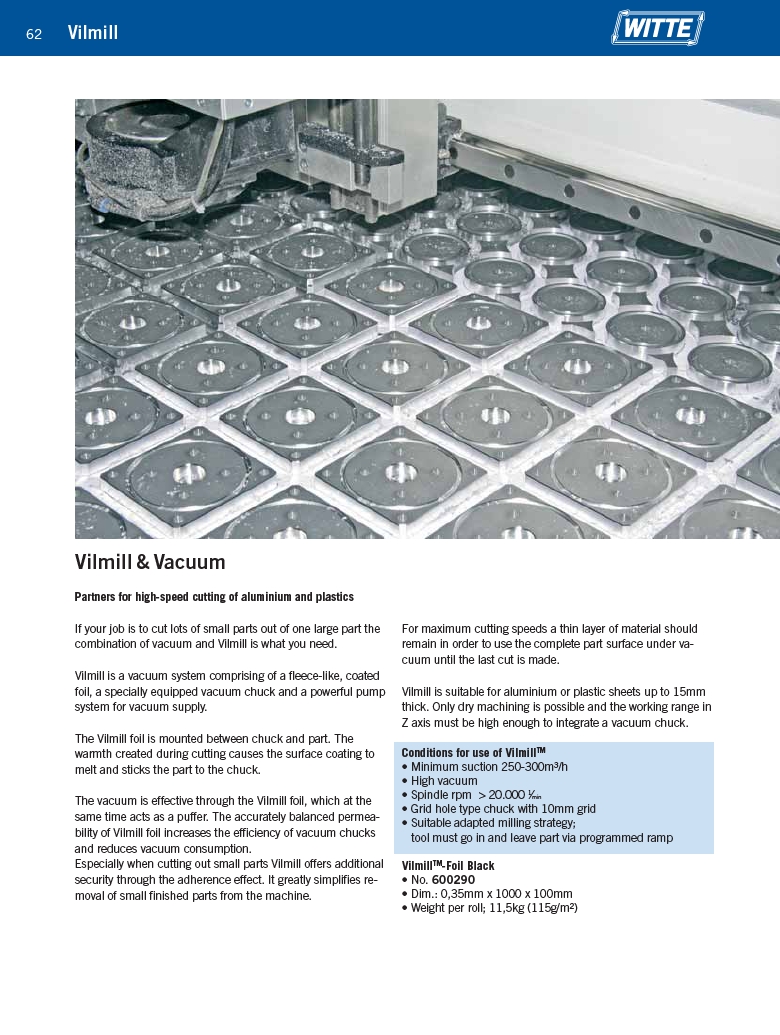

Vilmill is a vacuum system comprising of a fleece-like, coated

foil, a specially equipped vacuum chuck and a powerful pump

system for vacuum supply.

The Vilmill foil is mounted between chuck and part. The

warmth created during cutting causes the surface coating to

melt and sticks the part to the chuck.

The vacuum is effective through the Vilmill foil, which at the

same time acts as a puffer. The accurately balanced permeability

of Vilmill foil increases the efficiency of vacuum chucks

and reduces vacuum consumption.

Especially when cutting out small parts Vilmill offers additional

security through the adherence effect. It greatly simplifies removal

of small finished parts from the machine.

For maximum cutting speeds a thin layer of material should

remain in order to use the complete part surface under vacuum

until the last cut is made.

Vilmill is suitable for aluminium or plastic sheets up to 15mm

thick. Only dry machining is possible and the working range in

Z axis must be high enough to integrate a vacuum chuck.

Conditions for use of VilmillTM

• Minimum suction 250-300m³/h

• High vacuum

• Spindle rpm > 20.000 1⁄min

• Grid hole type chuck with 10mm grid

• Suitable adapted milling strategy;

tool must go in and leave part via programmed ramp

VilmillTM-Foil Black

• No. 600290

• Dim.: 0,35mm x 1000 x 100mm

• Weight per roll; 11,5kg (115g/m²)