104

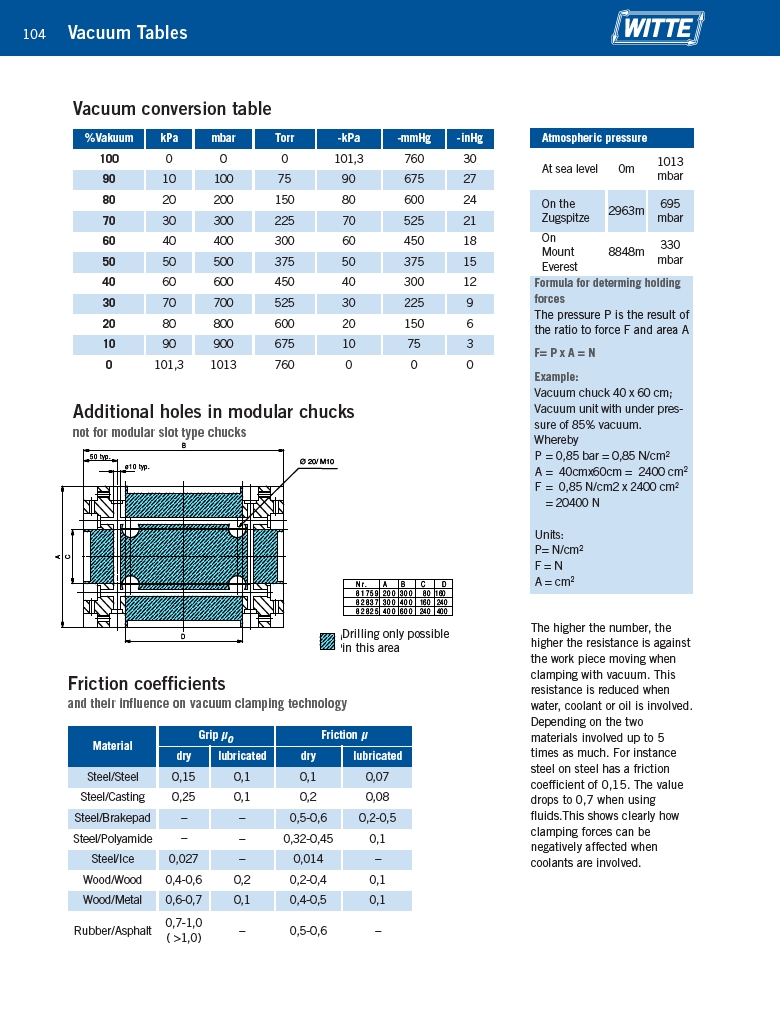

%Vakuum kPa mbar Torr -kPa -mmHg -inHg

100 0 0 0 101,3 760 30

90 10 100 75 90 675 27

80 20 200 150 80 600 24

70 30 300 225 70 525 21

60 40 400 300 60 450 18

50 50 500 375 50 375 15

40 60 600 450 40 300 12

30 70 700 525 30 225 9

20 80 800 600 20 150 6

10 90 900 675 10 75 3

0 101,3 1013 760 0 0 0

B

A

50 typ.

Ø 20/ M10

N r . A B C D

8 1 7 5 9 2 0 0 3 0 0 �� �� ������

8 2 8 3 7 3 0 0 4 0 0 ������ ������

8 2 8 2 5 4 0 0 6 0 0 ������ ������

in diesem Bereich kann gebohrt werden,

unter Berücksichtigung der Versorgungsbohrungen!

ø10 typ.

C

D

Drilling only possible

in this area

Vacuum Tables

Vacuum conversion table

Material

Grip μo Friction μ

dry lubricated dry lubricated

Steel/Steel 0,15 0,1 0,1 0,07

Steel/Casting 0,25 0,1 0,2 0,08

Steel/Brakepad – – 0,5-0,6 0,2-0,5

Steel/Polyamide – – 0,32-0,45 0,1

Steel/Ice 0,027 – 0,014 –

Wood/Wood 0,4-0,6 0,2 0,2-0,4 0,1

Wood/Metal 0,6-0,7 0,1 0,4-0,5 0,1

Rubber/Asphalt

0,7-1,0

( >1,0)

– 0,5-0,6 –

Atmospheric pressure

At sea level 0m

1013

mbar

On the

Zugspitze

2963m

695

mbar

On

Mount

Everest

8848m

330

mbar

Additional holes in modular chucks

not for modular slot type chucks

Friction coefficients

and their influence on vacuum clamping technology

Formula for determing holding

forces

The pressure P is the result of

the ratio to force F and area A

F= P x A = N

Example:

Vacuum chuck 40 x 60 cm;

Vacuum unit with under pressure

of 85% vacuum.

Whereby

P = 0,85 bar = 0,85 N/cm2

A = 40cmx60cm = 2400 cm2

F = 0,85 N/cm2 x 2400 cm2

= 20400 N

Units:

P= N/cm2

F = N

A = cm2

The higher the number, the

higher the resistance is against

the work piece moving when

clamping with vacuum. This

resistance is reduced when

water, coolant or oil is involved.

Depending on the two

materials involved up to 5

times as much. For instance

steel on steel has a friction

coefficient of 0,15. The value

drops to 0,7 when using

fluids.This shows clearly how

clamping forces can be

negatively affected when

coolants are involved.