EXAMPLES 205

Meisterbocks, Outline

gauges, Cubings

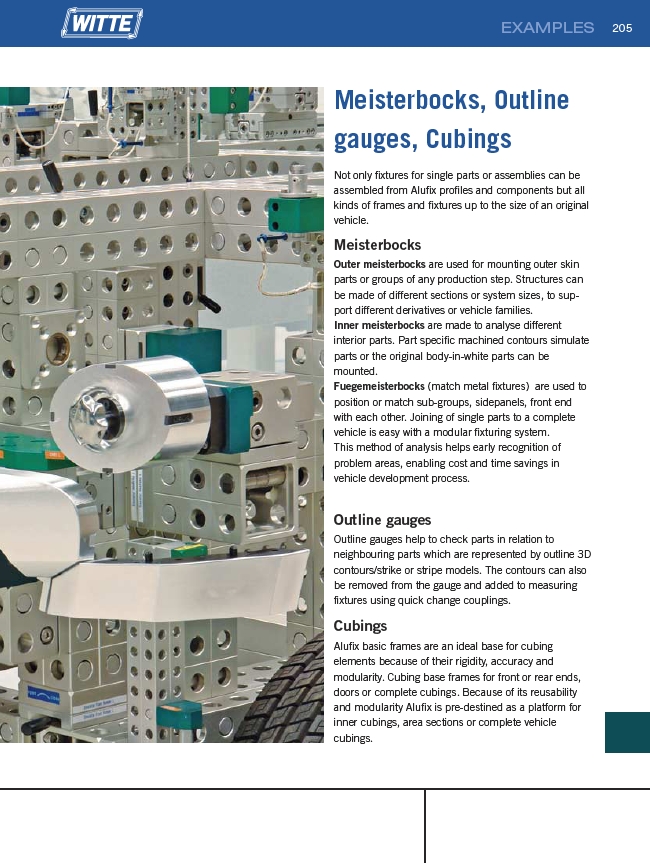

Not only fixtures for single parts or assemblies can be

assembled from Alufix profiles and components but all

kinds of frames and fixtures up to the size of an original

vehicle.

Meisterbocks

Outer meisterbocks are used for mounting outer skin

parts or groups of any production step. Structures can

be made of different sections or system sizes, to support

different derivatives or vehicle families.

Inner meisterbocks are made to analyse different

interior parts. Part specific machined contours simulate

parts or the original body-in-white parts can be

mounted.

Fuegemeisterbocks (match metal fixtures) are used to

position or match sub-groups, sidepanels, front end

with each other. Joining of single parts to a complete

vehicle is easy with a modular fixturing system.

This method of analysis helps early recognition of

problem areas, enabling cost and time savings in

vehicle development process.

Outline gauges

Outline gauges help to check parts in relation to

neighbouring parts which are represented by outline 3D

contours/strike or stripe models. The contours can also

be removed from the gauge and added to measuring

fixtures using quick change couplings.

Cubings

Alufix basic frames are an ideal base for cubing

elements because of their rigidity, accuracy and

modularity. Cubing base frames for front or rear ends,

doors or complete cubings. Because of its reusability

and modularity Alufix is pre-destined as a platform for

inner cubings, area sections or complete vehicle

cubings.